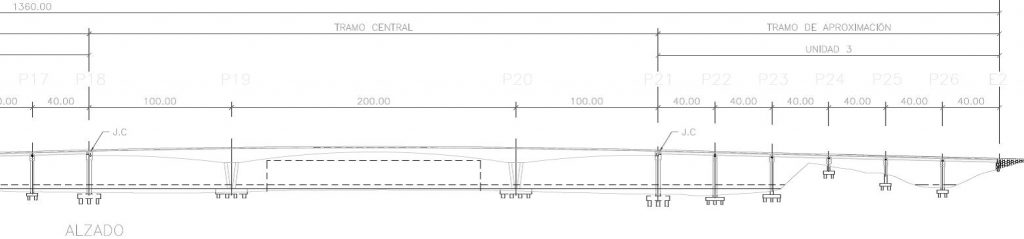

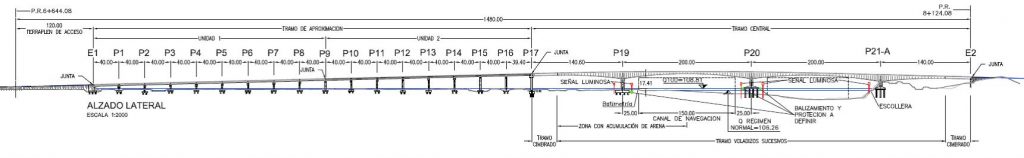

The Project of the Bridge Over the River Magdalena consists on a road Bridge 1360 m long, being the span distribution 17 x 40.0 + 140.0 +2 x 200.0 + 140.0.

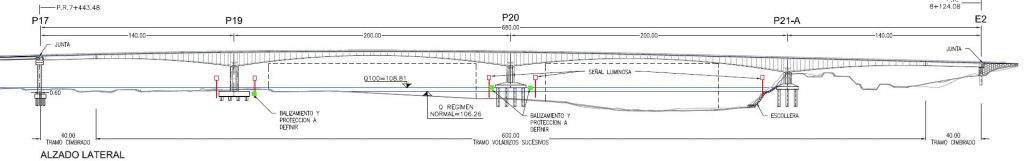

The main bridge was initially conceived as a frame, with a main span 200 m long and two side spans of 100 m, and two V piers encastred into the deck. While the foundations were under construction, the expected 100 years scour occurred, so it was not possible to finish the remaining foundations. This compelled to modify the span length distribution and the horizontal configuration, that was changed to seismic isolation of the deck, using lead bearings and vertical piers over the constructed foundations.

It is a concession signed by the National Infrastructure Agency (ANI), initially awarded to OHL and whose construction has been completed by Aleática.

The main section originally consisted of a portico with a span of 200 meters of span and compensation spans of 100 m, with V-shaped piers embedded in the deck.

During the construction of the foundations, the scouring expected in 100 years occurred, which made the construction of the foundations that were not already finished unfeasible, and forced to modify the distribution of lights and with it the configuration against horizontal loads, with lead core seismic isolators.

OHL commissioned Carlos Fernández Casado S.L. technical support to propose a solution to this problem. After evaluating various alternatives, the conclusion reached was that it was advisable to double the 200 m span extending the new span to the right bank to save the area where the installation of batteries in the water was planned in the initial project.

General elevation of main bridge original project

The configuration envisaged in the original design with V-frames for the main span of 200 m was shown to be not suitable for the bridge with four spans, given that the reduced height of the piers provided excessive rigidity of the system against longitudinal movements. caused by temperature and rheological effects, which produced a level of reactions incompatible with the foundations already built. For this reason, the design of these piers was changed to vertical elements with a single support in which, to optimize the seismic behavior, a solution of isolation and damping by means of LRB was used.

In parallel, it was proposed to adjust the compensation spans by extending them so that they were greater than the middle of the central span, a favorable configuration with regard to prestressing and to avoid lifting reactions in the end piers. This led to the initial project P18 not being necessary.

Once the solution was approved by the authorities, CFC developed the corresponding modified project for OHL and at the same time has carried out the technical support work for the construction.

Solution Description

Access Viaduct

The spans of the access spans of 40.0 m allow to optimize the cost ratio of a deck of prestressed beams that facilitates the construction independent of the conditions of the land in terms of the flood situation, and a cost of piles and foundations high by the poor resistant conditions of an alluvial type soil.

The access spans have a constant depth of 2.0 m. The section is made up of 4 pre-tensioned beams 3.45 m apart and 1.87 m deep. The webs have a constant thickness of 0.15 m and the upper slab of 0.23 m, with flights of 0.70 m.

The access spans beams are prestressed with 14 mm chords with a straight line adapted to the construction, providing continuity between beams by means of a reinforced concrete brace.

Main Bridge

The light distribution of the main bridge is 140.0 m +2 x 200.0 m + 140.0 m.

The final fitting of lights has made it possible to provide an adequate technical response to all the conditions raised in the study of alternatives. By doubling the main span over the river, of 200.0 m, the construction of the foundations of the intermediate piers with floating media has been avoided.

The total width of the deck is 12.95 m. The main spans have a parabolic depth variation between 10.0 m in the support section and 3.0 m in the center span section.

The deck of the main spans is prestressed with tendons of 19 strands of 14 mm with a breaking stress fpu = 1860 MPa.

The pier brace has been designed as a frame in which the webs are increased and the lower two meters are solidified to provide the provisional vertical prestressing anchors and collect the bending introduced by the definitive supports, since 5 have been arranged in the central alignment.

The main piers, from P19 to P21A, have an octagonal hollow section at the base and solid at the top.

The left abutment is proposed as a closed classical abutment with a pile cap and piloted, and the right abutment, as a piloted loading dock, with 1.6m diameter piles.

Seismic Isolation

The deck is supported on the stirrups and on piers 9 and 18 on support devices such as neoprene Teflon in box with transverse stops. In the piles 1 to 8 and 10 to 17 there are support devices made of high damping neoprene. In the central piles of the main section, piles 19, 20 and 21-A, each one has 5 seismic isolators of neoprene with lead core and high damping. Each support has a capacity of 25,000 kN at vertical load, with maximum allowable displacements of 40 cm for the extreme combination.

The seismic actions are resisted in the abutments and piers transversely individually while the longitudinal seismic action is resisted by all piers except 9 and 17. At the ends of the bridge as well as piers 9 and 17 there are joints of Elastomeric type dilation with the necessary capacity for movement.

Building process

The work on the bridge over the Magdalena River began with the construction of the foundations. During its execution, the undermining of the river bed and the rise of the water level occurred.

Due to the difficulty of using floating media, the height of the pile cap 20 was raised, increasing the piles already built and making the pile cap construction independent from the water level, by means of pre-slabs supported on an auxiliary structure and this in turn on the sleeves. of the piles.

The piers are built with climbing formwork.

The access spans are executed span by span by means of cranes that allow the construction of the deck to be made independent from the ground conditions.

The main spans are made by means of successive cantilevers balanced from the P-19, P-20 and P-21-A piers. In addition, a 40-meter section between P17 and the eliminated P18, and the last 40-m span between the last segment of P21-A and abutment 2 are built.

6 concreting cars have been used that have allowed the construction of the three cantilevers simultaneously.

The segments have a variable length of between 2.75 m and 5.0 m, and a maximum weight of 180 t.

The configuration of the bridge with compensation spans greater than half the main span, built by successive cantilevers adds an additional complication to the geometric control of the deck, because the construction countershafts are not symmetrical, it is necessary to take into account the turns that they will be produced when the ends of the spans are lowered. In addition, the lights considered make it necessary to consider the creep that occurs during construction to obtain the deformations.

Once the construction of the box is finished, the supports are replaced after lifting the deck with hydraulic jacks.